In 2020 we detected 2 TWh of energy losses for all our customers, which is the electricity consumption of a city of the size of Toulouse over one year and represents more than 90 million euros of revenues losses. This also corresponds to 980,000 tons of CO2 that could be avoided, nearly 5,700 Paris/New York flights or 1 million new vegetarians.

Power plants are seeking solutions to improve efficiency, to lower environmental harm, and reliably diagnose problems to tackle maintenance costs.

Metroscope helps them via its Monitoring & Diagnostics Software by supporting operators from data exploration to detection of abnormal behavior and to the automated identification of faults, also known as root cause analysis.

The software is powered by our proprietary technology.

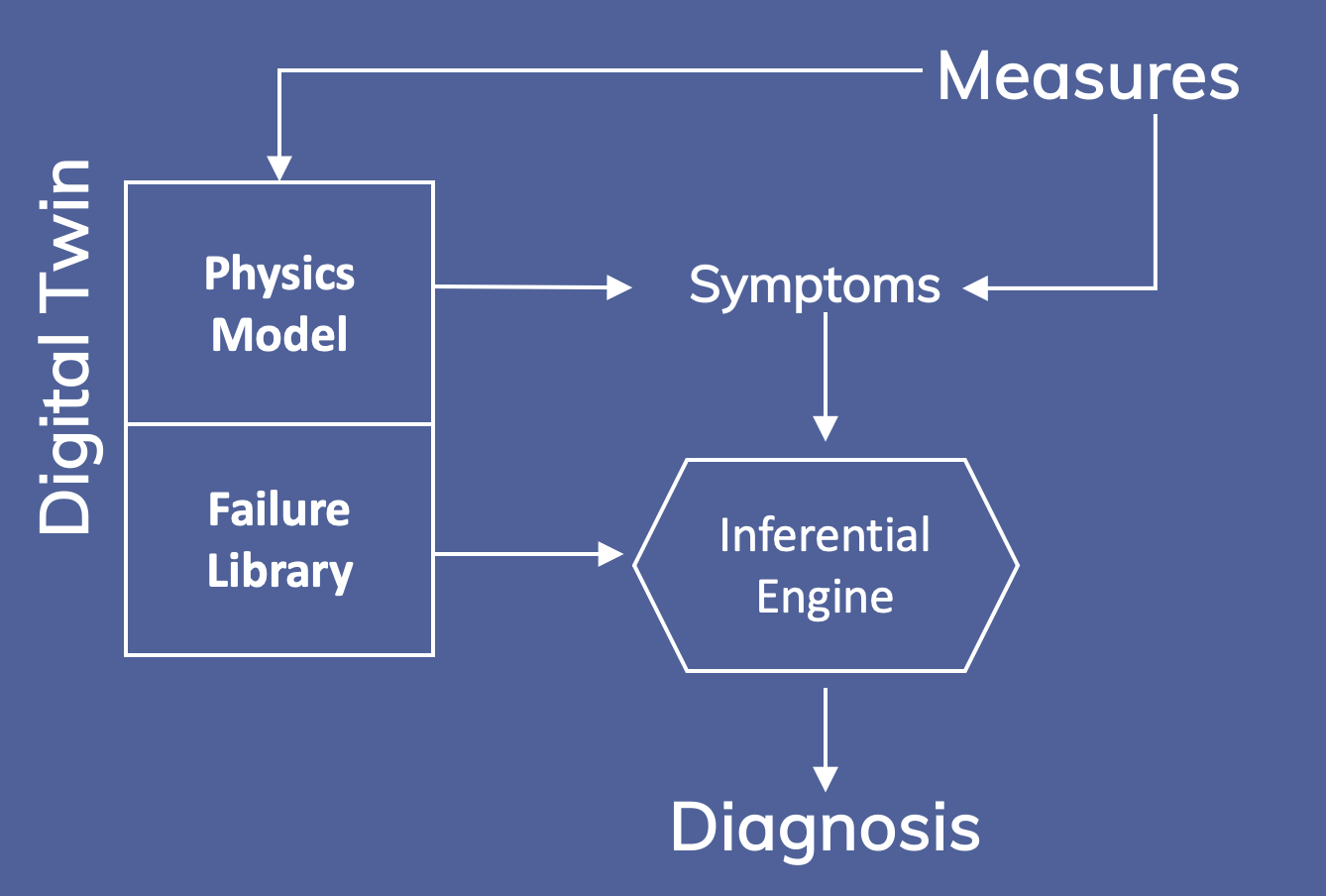

The Digital Twin provides both the ideal behavior of the plant and its faulty behavior through simulation. It is governed by an inferential engine to find the best scenario of faults that explains emerging issues.

For each diagnostic, the software will quantify the magnitude of the faults, its impact on the overall process performance and the level of trust of the detection.

Our case studies all come from real plants experience and relate to areas of concern such as condition-based maintenance, performance management and early-stage detection.

Last year Metroscope detected 2 TWh of lost energy on 60 power plants around the world with above 90% diagnostics reliability. Its trustworthy results help to reduce unnecessary volumes of maintenance and improve the overall asset's efficiency. 2 TWh correspond to 980,000 tons of CO2 avoidable, if we consider that each MW of nuclear power erases one MW of gas production (marginal production method) with a cost of 490gCO2eq/kWh.

How does Metroscope help recover MWh?

By automatically diagnosing ongoing faults and quantifying their impact on performance, operators can:

- detect early-stage faults whose symptoms wouldn't be recognizable otherwise

- fasten their decision-making process thanks to the 90% reliability rate of the software

- prioritize and justify interventions according to the objective quantification of the severity of the fault

- verify the impact of their own maintenance immediately after the intervention

Furthermore, the value of the software is not limited to the direct benefits in terms of fuel economy, MW increased production and CO2 reduction.

Metroscope impacts other areas such as: maintenance planning, knowledge management, skill management ...The software also eases transparency and transversal communication within the same organization thanks to a common view of the problems, from on-site teams up to corporate level. Metroscope also serves as a reliable memory of the asset's history and should naturally become a unique source of knowledge for all stakeholders.